PROCESS KNOW-HOW

Manufacturing

By using the state of art process and equipment which we constantly invest, we offer our customers the best quality. Our sustainable investment is also a crucial factor for success. Our computer-aided manufacturing systems (CAM) are increasingly merging construction design with manufacturing. Continuous personal development, high quality standards and reliable craftsmanship are what make us distinguished. Only in this way, we have no challenges we are afraid to face; We are pleased to undertake all kinds of projects from our customers and open to all kinds of new ideas.

In the area of machining, we can provide our customers with various CNC-milling centers at their disposal. Components with max. sizes of X=6.0m x Y=3.8m x Z=2.0m can be machined.

Other key areas of our production facilities

● Traditional model and mold manufacture

● Rapid prototyping technology

● Turning technology

● Grinding technology

● Surface finishing

● Measurement technology

● Assembly & adjustment

● Painting shop

+ Design & Check Models

Firstly there is the customer's vision, then the physical model. Any design comes from the customer's ideas and sketches. By creating a virtual digital model and subsequently fabricating physical model, we turn the customer's vision into reality. In the entire design and development phase, we constantly pursue the highest quality and maximum flexibility, and skillfully implement project management to strictly abide by the delivery date. Modern machine park and highly qualified technical team help us achieve these objectives. We mainly focus on

Design models: clay & solid models, see & go through models, aerodynamics model, concept & show cars etc.

Design verification models: HMI model, seating & color bucks interior/exterior, material concept model, design clinic model, integrated design model, design experience vehicle, data control model, refinement car etc.

+ Cubing & Master Boxes

Cubing or master box provides us not only with detailed information about building and matching ability of components and attachments before final assembly and achievable assembly accuracy, but also with means to assure assembly quality in the subsequent manufacturing process. This also means that error sources can be detected and eliminated in the early stage. As a full-service engineering supplier, we provide customers with all-round professional support from data management to completion of cubing or master box. Whether partial or complete cubing, we support our customers in the entire cubing process, from technical consultation, conceptual design, data management, construction design, manufacturing and delivery, as well as installation, commissioning and technical training at the end user's site, if necessary

In close cooperation with European engineering design companies and raw materials steel inserts norm part and metal 3D printing suppliers, we also provide with localized manufacturing, engineering changes and other after-sales services of modular and lightweight cubing acc. to EU standard. At the same time, we are going to introduce all carbon fiber composite ultralight cubing technology from Europe to further improve repetitive accuracy of cubing and significantly reduce manufacturing cost

Through close cooperation with European high precision profile suppliers based on modular brick system concept, we can also localize construction design, processing, assembly, commissioning and delivery of interior & exterior master boxes and floor & chassis gap master boxes

+ Flexible & Conventional Measurement Racks

Based on our solid design and manufacturing experience of traditional measurement racks, we are developing a new generation of mechatronic flexible measurement racks. With a wide range application of database software based optical and intelligent measurement technology, flexible measurement racks are becoming main hardware fundament leading to Industry 4.0 optical measurement technology

+ Testing Equipment & Gauges

In order to evaluate design accuracy of individual components or systems without existing measurement system, it is necessary to make test equipment & gauges to simply and quickly verify their design quality. Our test equipment & gauges can be applied to various test conditions and temperatures. We design and customize right test equipment & gauges for our customers, such as HMI test bench, motion track verification fixtures of electric swing door etc.

Here again, lightweight structure is more in demand than ever with the advantages: low production costs because tools can be used for duplicate creation; about 70% - 80% lighter than conventional aluminum gauges, reduced risk of accidents, easier operation, lower transportation costs, improved handling and ergonomics; no balance weight required due to light weight, therefore flexible and versatile, high rigidity; temperature insensitivity

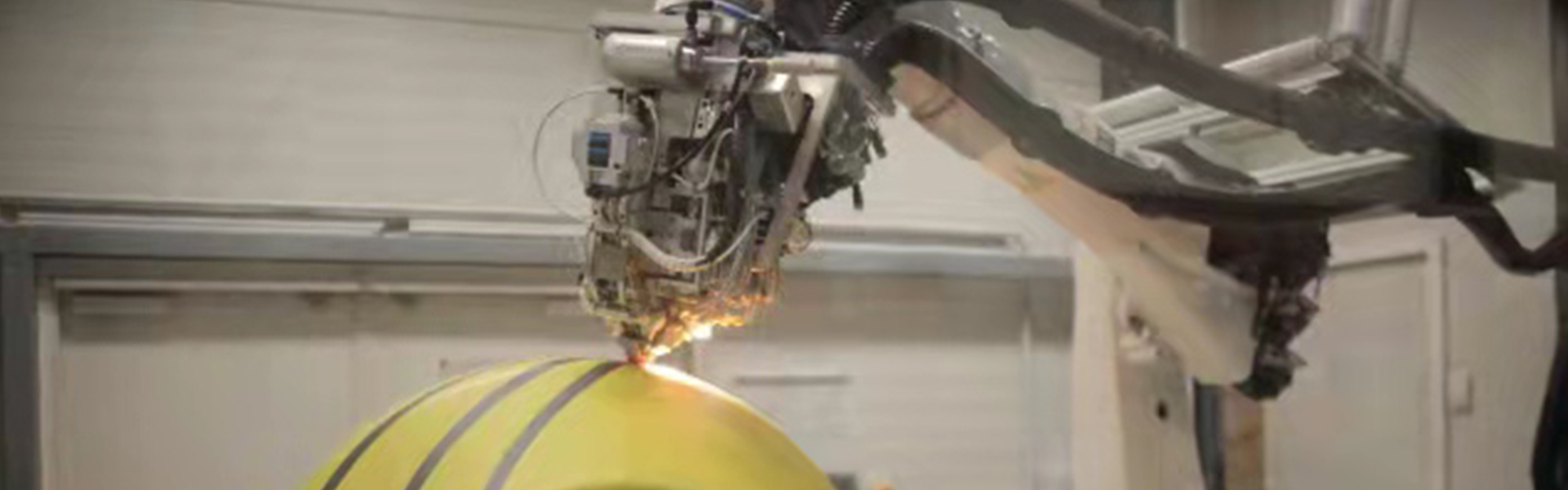

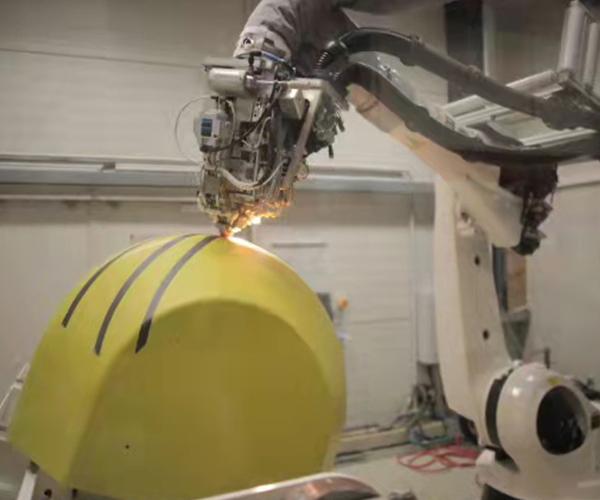

+ Moulds & Fixtures for Aluminium, Ureol & Composite

Thanks to our many years of specialized experience in moulds & fixtures for aluminum, ureol & composite, we have accumulated substantial know-how and are constantly improving and developing our competencies. Different methods for manufacturing of moulds & fixtures such as automatic multi-fibre patch placement moulds, holders and manipulators with software simulation technology are used here. The maximum mould dimensions are 5.0m x 2.4m x 1.8m.